|

Product Name: Heavy-duty Slat Feeder |

|

Applicable scope: |

Heavy-duty Slat Feeders are widely used in industrial sectors such as mining, metallurgy, building materials, and coal carbon. This machine is mainly used under material silos and funnels to transport large amounts of materials uniformly and continuously over short distances to designated locations, in order to complete subsequent continuous operations. Materials with large volume and density can be transported under severe weather conditions (rainstorm and hail). The machine can be installed horizontally or obliquely, with a maximum tilt angle of 23 ° for upward transportation.

|

Structural characteristics and working principle: |

Heavy-duty Slat Feeder component; ⑴ The drive device, ⑵ chain plate device, ⑶ main shaft device, ⑶ tensioning device, ⑤ frame, ⑥ supporting wheel, ⑦ support sprocket, and other components are composed. The device is a straight axis pivot floating type, with the main spindle installed in the output shaft of the planetary reducer. The two are connected by a locking plate. Its characteristics are suspension without foundation, light weight, and high speed ratio. Due to the use of pivot floating, the additional bending moment generated by installation errors on the shaft is reduced, and the service life of the transmission shaft is improved, making disassembly and assembly convenient.

The Heavy-duty Slat Feeder is driven by the power of the motor through a coupling and a reducer to rotate the sprocket shaft and mesh with the chain pin shaft through the sprocket teeth, dragging the chain plate for continuous linear motion. The chain plate is supported by supporting wheels and supporting wheels installed on the frame, and the chain and sprocket are correctly engaged by adjusting the tensioning device to complete continuous transportation of materials.

|

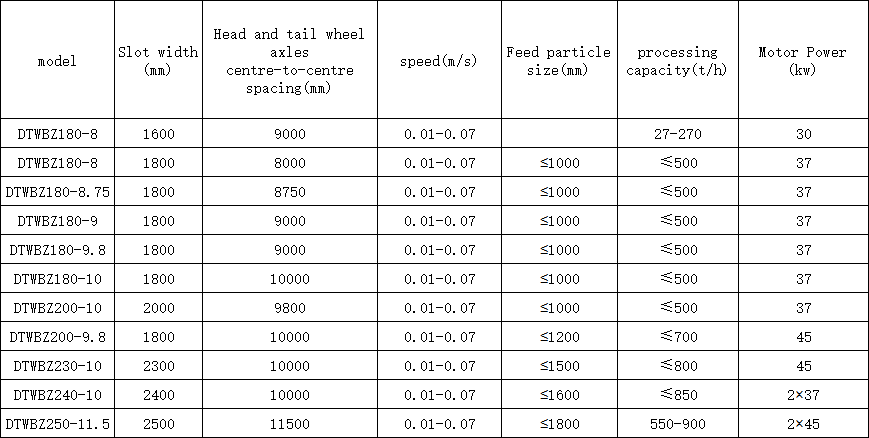

Technical parameters (For reference) |