|

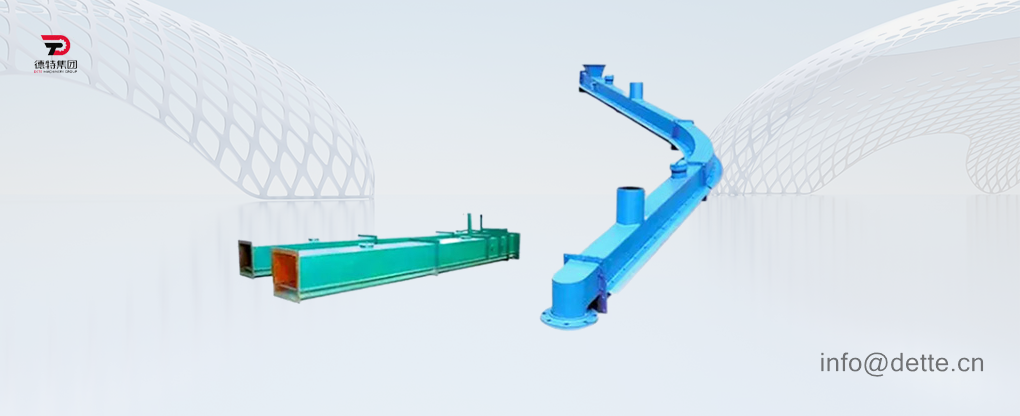

Product name: Air slide |

|

Product Introduction: |

Air slide is used for inclined downward transport of dry powder materials such as cement, raw materials, fly ash, talc powder, phosphate mill powder, etc.

|

Equipment advantages: |

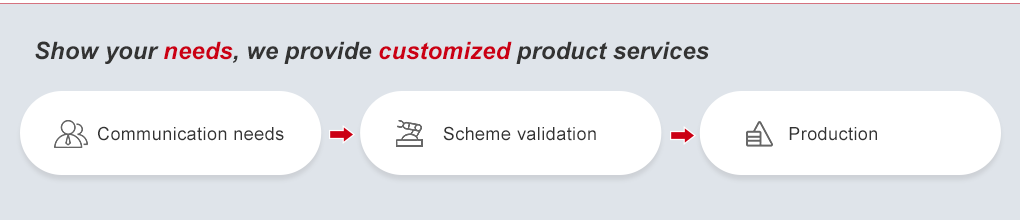

The air slide is composed of several thin steel slots connected and arranged in a certain slope along the conveying direction. There is a breathable layer between the upper and lower shells of the tank body. In the conveying process, it is easy to change the conveying direction, and multi-mouth feeding can also be set. The power source provided by the high-pressure centrifugal fan (9-19-9-26 type) keeps the material in the closed conveyor chute fluid and flows to a section in the inclined direction. The main part of the equipment has no mechanical operating parts, no wear; The breathable layer adopts a new type of coating. The overall operation is convenient, with light weight, small power consumption, large transmission capacity and other advantages.

|

Equipment principle: |

The air slide is divided into upper and lower layers by the breathable layer, and the powder material falls into the upper layer of the chute through the feed pipe. The compressed air generated by the blower enters the lower layer of the tank through the soft nozzle, and the air passes through the pores of the breathable layer, making the upper material aerated into a fluid state. The fluid material flows from the upper part of the tank to the lower part by the action of gravity like a liquid. The air entering the upper tank is discharged through the filter.

|

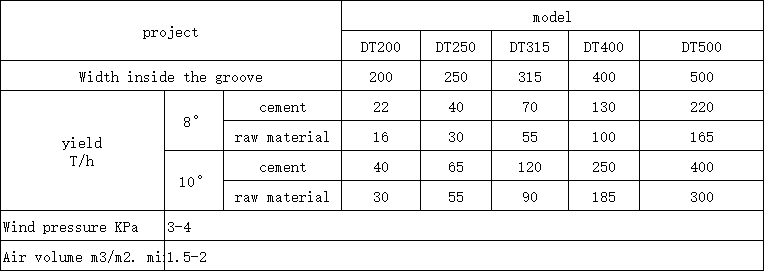

Technical parameters (For reference) |

|

Application field: |

Air slide is used for inclined downward transport of dry powder materials (such as cement, raw materials, fly ash, flour, talc powder, phosphate rock powder, etc.). The chute has no rotating parts in the process of conveying materials, easy maintenance, good sealing, no noise, safe and reliable operation, less power consumption, large conveying capacity, easy to change the direction, and can be widely used in multiple stores for feeding and unloading.