|

Product Name: Elevating Conveyor |

|

Product Introduction: |

Elevating Conveyor is a widely used vertical lifting equipment in the cement industry, mainly used in the lifting and conveying process of cement materials in cement projects.

1. Widely improve materials.

2. Strong lifting ability, output range of 40-1100m3/n, up to 1600m3/n, lifting height of up to 50 meters.

3. Long service life.

4. Safe and reliable operation, low failure rate, convenient maintenance and repair, few vulnerable parts, and low operating costs.

|

Equipment principle: |

|

Structure introduction: |

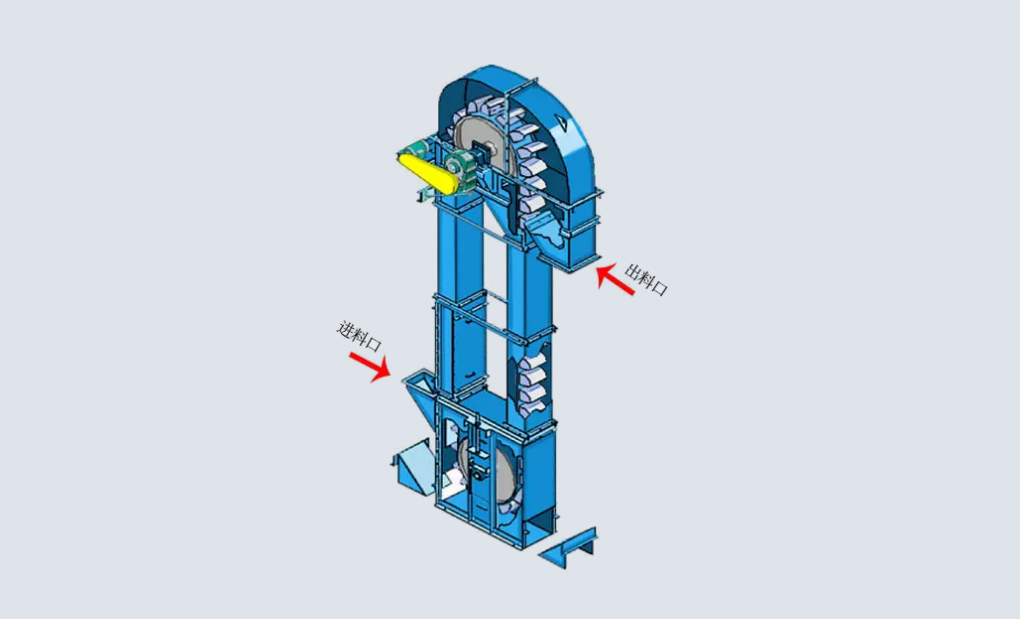

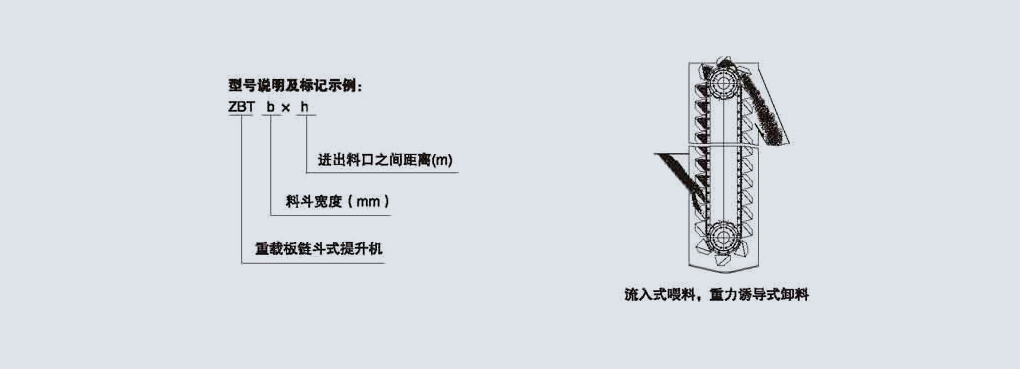

The ZBT heavy-duty plate chain bucket elevator is composed of a bottom casing, a tensioning device, a middle casing, a head casing, a driving mechanism, a dragging mechanism, a chain, and a hopper.

1. Bottom casing:

The bottom of the casing is connected to the foundation with anchor bolts, and the top flange is connected to the middle casing. There are no three access doors, one cleaning door, one feeding port, and a lifting crossbeam for installing the tensioning device on the bottom shell. Installation of drag chains, hoppers, and maintenance of machinery can all be carried out at the bottom inspection port. The cleaning door can be used to clean the accumulated material at the bottom.

2. Tensioning device:

The tensioning device is located at the bottom of the casing and adopts a counterweight automatic tensioning device. The tensioning force is constant and the tensioning stroke is long.

3. Intermediate casing

The standard height of the middle casing is 2m. To meet the needs of different lifting heights, non-standard casings can be added for adjustment. To ensure smooth operation, the middle casing is equipped with guide rails.

4. Upper section:

The upper section consists of a head shell, a driving mechanism, a driving mechanism, a maintenance platform, etc. The head shell is equipped with one cleaning door and one observation door. When the cleaning door is used to clean the dirt on the hopper and sprocket inside the shell; The observation door is used to check the operation and wear of the sprocket, the unloading situation of the hopper, and the replacement of the rubber lip at the discharge port. The driving mechanism includes a check motor, a reducer, and a coupling. The drag mechanism includes lifting sprockets, main shafts, bearing seats, etc.

5. Traction chain:

The traction chain adopts a plate sleeve roller chain, and the chain plate, sleeve, and pin shaft are all made of alloy structure and processed through special heat treatment. It has the advantages of high strength, long service life, large bearing capacity, easy disassembly, and reliable operation.

6. Hopper:

The hopper is connected to the chain by bolts. According to the different conveyed materials, there are two types of hoppers: ZH (medium depth) and SH (deep). The ZH type hopper is suitable for larger granular materials, while the SH type hopper is suitable for smaller granular and powdered materials.

|

Technical parameters (For reference) |

7. Elevating Conveyor has a complete range of models and is suitable for lifting from low to high. After the supplied materials are fed into the hopper through a vibration table, the machine automatically operates continuously and transports them upwards. The conveying speed can be adjusted according to the conveying amount, and the lifting height can be selected as needed. The hopper is a self-designed and manufactured NE500 bucket elevator, and the PP non-toxic hopper makes this type of bucket elevator more widely used. All sizes are designed and manufactured according to actual needs for cement special bucket elevators, designed for supporting vertical packaging machines and computer measuring machines, suitable for lifting and feeding products in the cement industry, The automatic stop and start of the packaging machine can be controlled through signal recognition.