|

Product Name: Screw Conveyor |

|

Product Introduction: |

Used for conveying various powdery, granular, and small materials, such as cement, coal powder, etc. It is not suitable for conveying materials with high viscosity and block size that are prone to clumping.

|

Equipment advantages: |

Screw Conveyor, also known as twisted dragon, is an energy-saving and environmentally friendly equipment that can transport loose materials from multiple angles (0 ° -90 °). The material and structure of the equipment can be customized, and various loose materials such as powder, particle, and small pieces can be transported, such as coal, ash, slag, cement, grain, etc. Spiral conveyors are generally divided into two types: tubular and U-shaped, which have strong sealing properties, can transport powder materials without flying, and can reach a vertical conveying angle of 90 ° to transport materials;

The U-shaped screw conveyor has mature technology, is not easily damaged, and is easy to maintain. It can be processed by opening the cover plate,

Most of them are used for horizontal small angle conveying of granular materials (with an angle of 20 °).

In addition, after years of innovation, screw conveyors can now meet special needs such as weighing, dual axis, multi tube, and axle free.

Special attention: Not suitable for conveying materials with temperatures above 200 ℃, prone to spoilage, high viscosity, and prone to clumping.

|

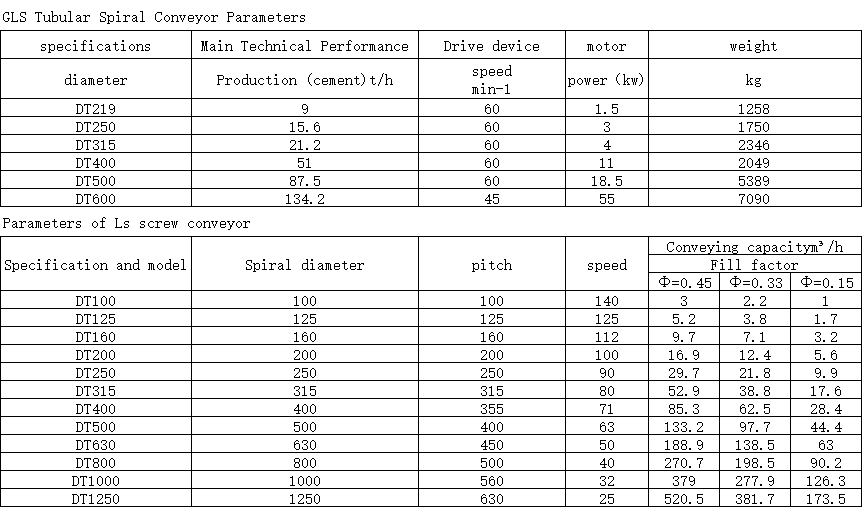

Technical parameters (For reference) |

|

Performance characteristics: |

1. High load-bearing capacity, safe and reliable.

2. Strong adaptability, easy installation and maintenance, and long service life.

3. The whole machine has a small volume, high speed, and ensures fast and uniform conveying.

4. The discharge end is equipped with a cleaning device, which has low noise and strong adaptability. The position of the inlet and outlet is flexible.

5. Good sealing performance, the shell is made of seamless steel pipes, and the ends are connected to each other by flanges, with good rigidity.

|

Working principle: |

When the spiral shaft rotates, due to the gravity of the material and its frictional force with the groove wall, the material can only move forward along the bottom of the conveyor groove under the push of the blades, just like a non rotating nut moving in translation along a rotating screw. The transportation of materials in the middle bearing relies on the thrust of the materials moving forward from behind. So, the transportation of materials in the conveyor is completely a sliding motion.

The head and tail bearings are moved outside the shell, and the suspension bearings are equipped with sliding bearings and dustproof sealing devices. The bearing shells are generally made of powder metallurgy, and felt bearing shells are used for conveying cement. The suspension shaft and spiral shaft are connected by sliding blocks.